About us

As dry ice blast cleaning experts, our goal is to render the best quality dry ice cleaning equipment and premier dry ice pellets for all your industrial cleaning requirements nationwide.

What Is Dry Ice Blasting?

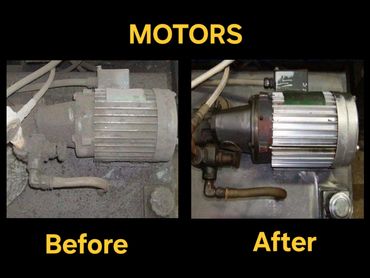

This process is called sublimation and is a unique characteristic of dry ice, which makes it ideal for cleaning a variety of industrial equipment in the form of electrical motors, stators, generators, electrical panels affected by flash or fire damage, as well as for the removal of mould, welding splatter, ink, glue, paint, food, rubber, dirt, grease, oil and numerous other contaminants.

How Does Dry Ice Blasting Work?

The dry ice freezes the dirt on impact, then rapidly sublimates while the CO2 gas removes the frozen dirt without causing damage or abrasion to the surface. Because of the temperature difference between the dry ice particles and the surface being treated, thermal shock occurs during the process. This causes a breakdown of the bond between the two dissimilar materials.

The dry ice pellets are accelerated up to 300 m/s (1,080 km/h) by the compressed air and then blasted onto the surface to be cleaned. The second part of the cleaning process is the impact with high kinetic energy.

REASONS TO CHOOSE DRY-ICE-BLASTING

Safe for Workers

Greater Productivity

Greater Productivity

We can blast close to products and work while the facilities are up and running.

Greater Productivity

Greater Productivity

Greater Productivity

Reduced Cleaning Time. Dry ice blasting can be 80% faster.

Non-Conductive

Greater Productivity

Non-Conductive

Does not conduct electricity. Dry ice blasting is a dry cleaning method.

Non-Flammable

Environmentally Safe

Non-Conductive

CO2 behaves like an inert substance. There is typically no chemical reaction with other substances.

Bacterial Control

Environmentally Safe

Environmentally Safe

Removes bacteria from surface being blasted.

Environmentally Safe

Environmentally Safe

Environmentally Safe

It's the most environmentally safe way to clean. No secondary waste generated. The only waste is from dirt and grime that has been removed.

Non-Toxic

Safe for Equipment

Safe for Equipment

CO2 is safer than toxic chemicals. Replaces substances harmful to the environment.

Safe for Equipment

Safe for Equipment

Safe for Equipment

Does not damage the surface being cleaned. Can be used around electrical components without risk of damage.

Before & After Blasting Gallery

Contact Us

We love our customers, so feel free to contact us during normal business hours.

Open today | 08:30 am – 08:30 am |

Subscribe

Sign up to hear from us about specials, sales, and events.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.